Read more here

Read more here

CILT Endorsed Materials and Supply Chain Management

DATE

Yet to be Determind

LOCATION

To be determined

Why Attend?

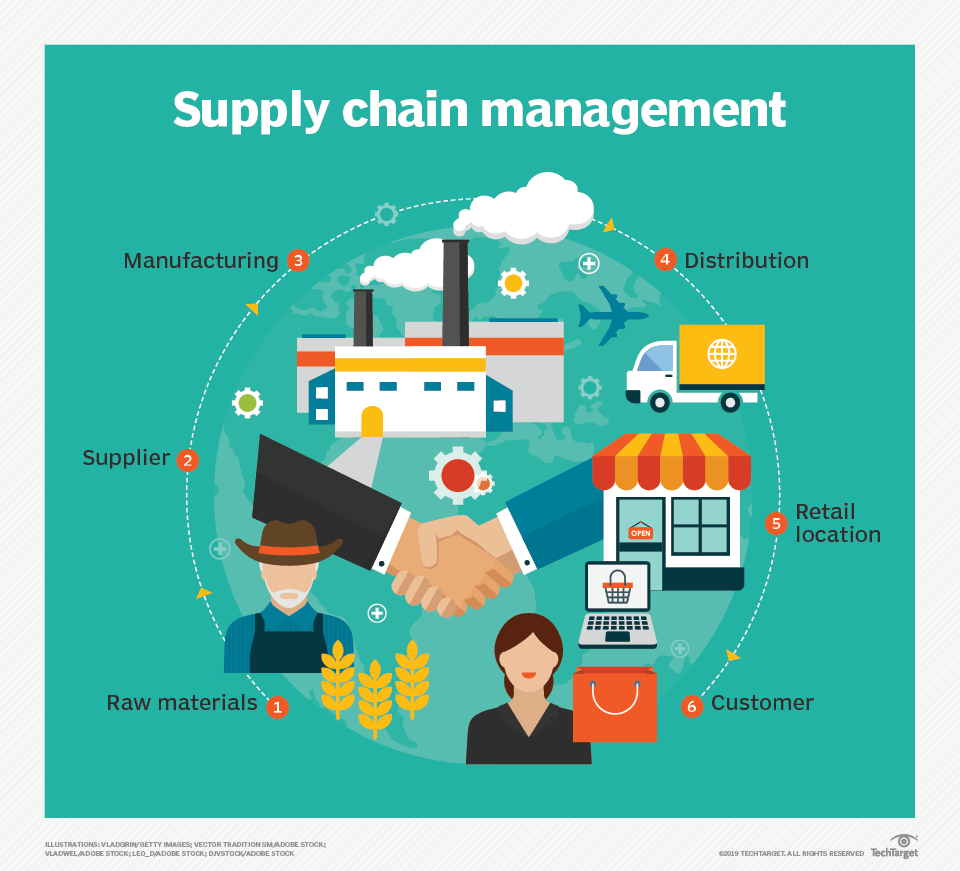

Supply Chain Management (SCM) has been consistently cited as one of the most critical processes in any operational company. The impact SCM has on business is major given that SCM impacts customer service and the bottom line. However, SCM is not easy given the dynamic nature of the many uncertainties involved. This dynamism has necessitated many companies to upgrade the skills of their SCM employees in order to capitalize on this untapped opportunity. In this course, many SCM best practices will be discussed, and the solutions provided will help participants deal with various scenarios to ensure the continuous flow of material at the least possible cost.

Course Objectives

Course Objectives

-

This Course Objective Hasn't Been Provided Yet

Target Audience

Target Audience

Those involved in any function of materials and supply chain management (inventory, warehousing, purchasing and transportation) who are concerned with successfully providing acceptable customer or user service at a minimum cost. This course is also appropriate for anyone who needs to know more about the role of materials management.

- Definition of materials and supply chain management

- Materials management scope

- The functions and objectives of materials management

- Types of inventory

- The importance of customer service in materials and supply chain

- Problems in materials management

- Computerized materials management applications

- Inventory planning and stock control

- Inventory systems

- The ABC classification

- Application of the ABC classification

- Forecasting and planning in materials management

- Typical demand trends

- Forecasting objectives

- Different forecasting models

- Qualitative forecasting

- Quantitative forecasting

- Evaluation of forecasts

- Materials planning and control

- Inventory costs

- The economic order quantity model

- How to deal with constrained quantity discount schemes

- The importance of controlling lead time

- The maximum/minimum system

- Setting the reorder points

- Setting safety stocks

- The purchasing function

- Basic purchasing process

- Skills of a purchasing professional

- Factors to consider when selecting suppliers

- Suppliers evaluation

- Changing trends in procurement

- Definition and application of Incoterms

- Negotiating with suppliers

- The warehousing function

- Warehousing objectives

- Inventory record accuracy requirements

- Calculating record accuracy

- Periodic cycle counting

- How to improve record accuracy

- The transport function

- Fleet and transport objectives

- Methods of transport

- Responsibilities of traffic

- Transport expenses

- Cost reduction opportunities

- Routing and cubing

Join Our Community